Industry / Innovation / Products

Technical Bulletin: Fire-Rated Assemblies

Maintaining a fire resistance rating in compromised floor-ceiling material

Why is a fire rated fixture important?

Many people live in multi-family homes where individual living spaces are accessed via common corridors, stairways and entry/exit doors. These common entry/exit passageways are constructed to provide approved levels of fire protection that enable occupants to safely exit the building in case of an emergency.

DMF Lighting provides luminaires, such as the DRDHNJD / DRD2M / DRD2T family, using OneFrame™ technology, which has a two-hour fire rating, which is code compliant for a maximum two-hour fire rating when installed in the appropriate fire-rated assembly. This is suitable for use in common entry/exit passageway applications when a fire rating is required.

What is the IBC?

The International Building Code® (IBC), developed by the International Code Council (ICC), is a model building code that has been adopted and used as a base code standard throughout most of the USA. The IBC® is a complex and lengthy document with comprehensive requirements. Chapter 7 on Fire and Smoke Protection Features is key, and in particular Section 714 Penetrations:

The provisions of this section shall govern the materials and methods of construction used to protect through penetrations and membrane penetrations of horizontal assemblies and fire-resistance-rated wall assemblies.

Penetrations of ceiling membranes are covered in Section 714.5 where subsection 714.5.2 Membrane Penetrations states:

Where floor/ceiling assemblies are required to have a fire-resistance rating, recessed fixtures shall be installed such that the required fire resistance will not be reduced.

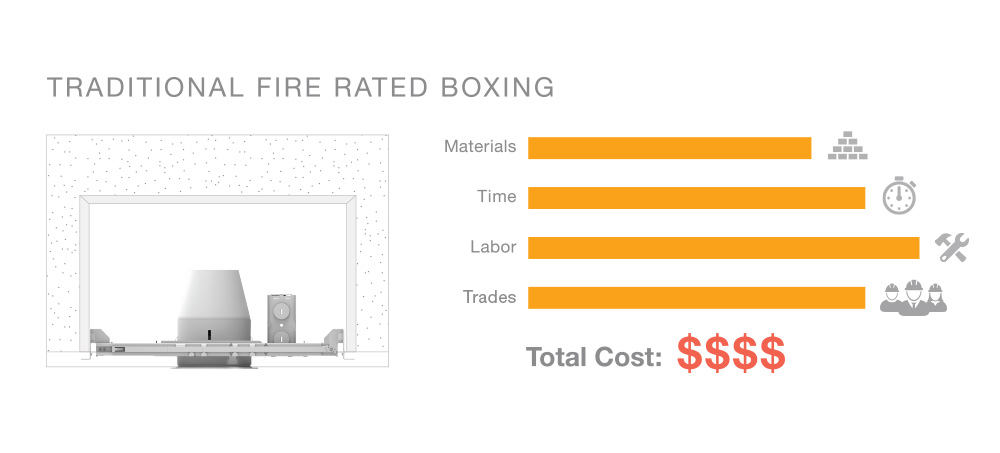

How can a recessed fixture be installed without reducing the fire rating of the floor/ceiling assembly? The traditional approach is shown in diagram below: Although this is an effective method, it requires the ceiling space to have boxed-out cavities, using the same fire-rated membrane material, to mount the recessed fixtures in. This approach adds significant costs and requires extra space above the ceiling plane that may not always be available.

Although this is an effective method, it requires the ceiling space to have boxed-out cavities, using the same fire-rated membrane material, to mount the recessed fixtures in. This approach adds significant costs and requires extra space above the ceiling plane that may not always be available.

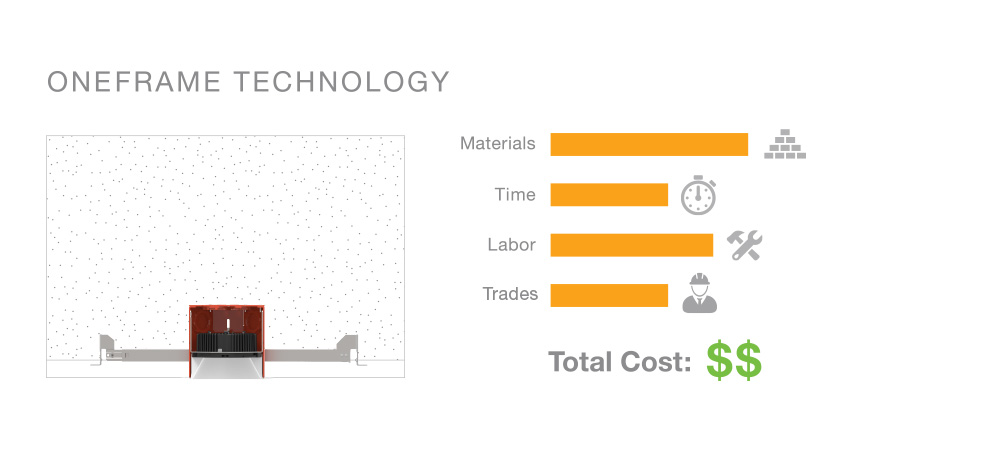

OneFrame™ technology provides a new method of achieving the same result and is shown in the diagram below: The OneFrame™ junction box reduces installation costs significantly because it eliminates the requirement to create boxed-out cavities at the time of construction by utilizing one of the exceptions provided by subsection 714.5.2:

The OneFrame™ junction box reduces installation costs significantly because it eliminates the requirement to create boxed-out cavities at the time of construction by utilizing one of the exceptions provided by subsection 714.5.2:

Ceiling membrane penetrations of maximum 2-hour horizontal assemblies by steel electrical boxes that do not exceed 16 square inches (10,323 mm²) in area, provided the aggregate area of such penetrations does not exceed 100 square inches (44,500 mm²) in any 100 square feet (9.29 m²) of ceiling area, and the annular space between the ceiling membrane and the box does not exceed 1/8 inch (3.2 mm).

UL 514A Standard for Safety – Metallic Outlet Boxes

One of the many UL listings OneFrame™ has been granted is QCIT.E469361. This UL listing states that OneFrame™ is a qualified metallic outlet box or in IBC terminology, steel electrical box. UL’s Fire-resistance Ratings – ANSI/UL 263 BXUV.GuideInfo states in section III – Floor-Ceilings and Roof-Ceilings, sub-section 6 – Metallic Electrical Outlet Boxes, can be used in fire-rated floor-ceiling and roof-ceiling assemblies, as described below:

Metallic outlet and switch boxes with metallic or nonmetallic cover plates may be used in floor-ceiling and roof-ceiling assemblies with ratings not exceeding 2 hours. These assemblies should have gypsum wallboard membranes. The metallic outlet boxes should be securely fastened to the joists and the opening in the gypsum board facing should be cut so that the clearance between the boxes and the gypsum board does not exceed 1/8 in. The surface area of individual boxes should not exceed 16 sq in. The aggregate surface area of the boxes does not exceed 100 sq in per 100 sq ft of ceiling surface.

Note the requirement for the contractor to create a tight, not to exceed 1/8” cut-out in the gypsum wallboard to ensure the integrity of the fire rated membrane.

OneFrame™ has also been granted an unparalleled combination of other safety certifications, including Sound, Air-Tight, Concrete-Tight, IC, and Wet Location ratings. You can be confident that OneFrame™ is compliant in a wide range of installations.